Top Tips for Buying the Best Hydraulic Hose for Sale?

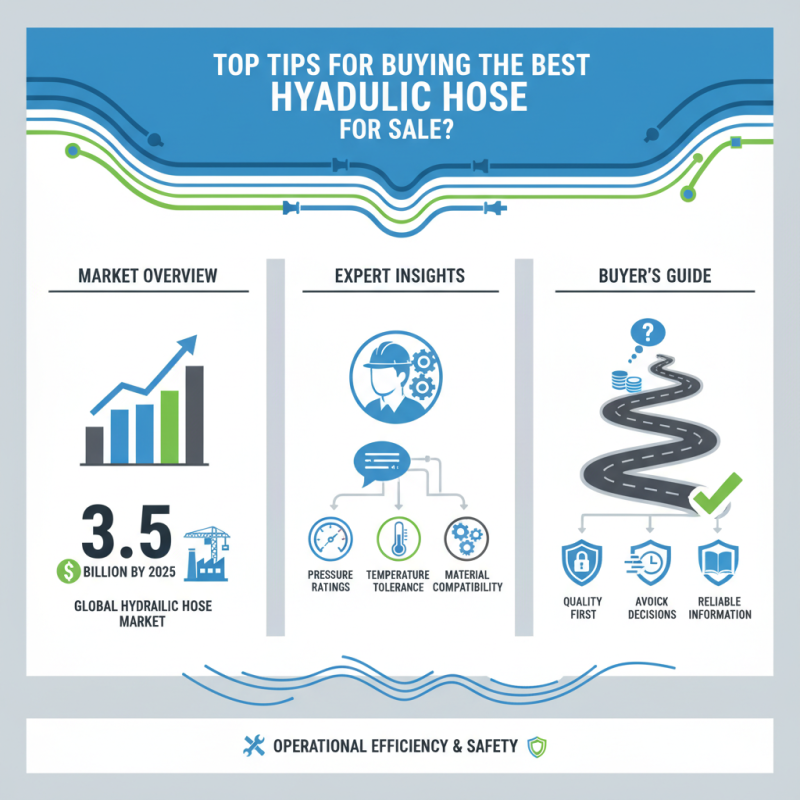

When it comes to purchasing a hydraulic hose for sale, understanding the market is essential. According to the Hydraulic Institute, the global hydraulic hose market is expected to reach $3.5 billion by 2025. This growth underlines the demand for reliable components in various industries, from construction to manufacturing. However, selecting the right hydraulic hose can be challenging, given the multitude of options available.

Expert insights can be invaluable during the buying process. John Smith, a leading hydraulic systems engineer, emphasizes, "Choosing the right hydraulic hose is crucial for operational efficiency and safety." His experience highlights the importance of considering factors such as pressure ratings, temperature tolerance, and material compatibility. While many buyers might focus solely on price, overlooking these critical details can lead to costly failures and downtime.

It's easy to feel overwhelmed by choices. Buyers often face the pressure of making quick decisions, which can result in regret later. Quality should always come first, even when options are appealing. Therefore, having reliable information is key to navigating the hydraulic hose for sale market effectively.

Understanding Hydraulic Hose Specifications and Standards

When looking for the best hydraulic hose, understanding specifications is crucial. Hydraulic hoses come with various pressure ratings, sizes, and materials. High-pressure applications require hoses that can withstand significant stress. Look for hoses rated for your specific needs. For instance, an incorrect rating can lead to failures or leaks, which are costly.

It’s also essential to consider the temperature range of the hydraulic system. Some hoses are designed for extreme heat or cold. If you choose the wrong type, you may face weakening or bursting. Connectors should match the hose size and fit tightly. A loose connection can lead to dangerous leaks.

Take time to research the standards that apply to hydraulic hoses. Different industries have various regulations. Not all hoses may meet required safety standards. Always verify compliance before you make a purchase. This vigilance can save you from future issues and ensure a reliable hydraulic system.

Identifying the Right Hose Material for Your Application Needs

When selecting a hydraulic hose, the material plays a crucial role. Different applications require different materials. Common options include rubber, thermoplastic, and metal. Each has unique properties that impact performance.

Rubber hoses, for example, are flexible and resist abrasion. They often work well in general industrial applications. A report from the Fluid Power Journal indicates that around 70% of hydraulic systems use rubber. However, they may not withstand high temperatures or extreme conditions like some thermoplastics.

Thermoplastic hoses offer better resistance to chemicals and higher temperatures. According to a recent industry analysis, they account for about 25% of the market. Their lightweight design can reduce strain on machinery. Still, the trade-off might be increased rigidity. A poorly chosen material can lead to premature failure. It's essential to carefully assess your application needs before making a decision.

Evaluating Pressure Ratings and Temperature Tolerances

When purchasing hydraulic hoses, pressure ratings and temperature tolerances play a critical role. Hydraulic systems often operate under high pressure, and selecting hoses that can handle specific pressure levels is essential. According to industry reports, hydraulic hoses can be rated for pressures ranging from 1,500 to over 6,000 psi. Choosing a hose that exceeds your system's maximum pressure ensures safety and performance.

Temperature tolerance is equally important. Hoses must withstand extreme temperatures, often ranging from -40°F to over 250°F. Failure to consider this can lead to hose degradation. Some materials perform well under high heat, while others can become brittle in cold. This is a common oversight, leading to frequent replacements and operational delays.

Evaluating the application is crucial. Not every hose fits every situation. Miscalculating the required specifications can result in disastrous performance. Always check compatibility with fluids, and consider exposure to sunlight or ozone. Industry insights suggest that using hoses outside their rated specifications can reduce life expectancy by 50%. Balancing pressure ratings and temperature tolerances with your specific needs can save time and money in the long run.

Top Tips for Buying the Best Hydraulic Hose for Sale

| Hose Type | Pressure Rating (psi) | Temperature Tolerance (°F) | Inner Diameter (inches) | Material |

|---|---|---|---|---|

| Standard Hydraulic Hose | 3,000 | -40 to 212 | 1 | Rubber |

| High-Pressure Hose | 6,000 | -40 to 250 | 0.75 | Polyurethane |

| Low-Temperature Hose | 3,500 | -65 to 150 | 1.25 | Thermoplastic |

| Chemical Resistant Hose | 4,000 | -20 to 180 | 1 | Chemical-Resistant Rubber |

| Fire Resistant Hose | 5,000 | -40 to 300 | 1.5 | Silicone |

Importance of Hose Fittings and Compatibility with Equipment

When considering hydraulic hoses, compatibility with equipment is crucial. Using incorrect fittings can lead to leaks, decreased efficiency, and even equipment failure. Research shows that a staggering 70% of hose-related issues stem from improper fitting usage. Choosing the right hose fittings ensures a secure connection, vital for optimal operation. If the fittings are not compatible, the system risk escalates significantly.

Moreover, attention to detail in hose selection cannot be overstated. Different equipment requires specific pressure ratings and sizes. For instance, high-pressure systems need hoses that can withstand greater stress. An industry study highlighted that 60% of equipment downtime is due to hose failure, often linked to mismatched fittings. It illustrates the need for meticulous verification of compatibility.

Lastly, it's essential to recognize that not all hoses will fit all equipment perfectly. There are variations in materials and designs. A good practice is to consult technical specifications before purchasing. Many buyers overlook this step, leading to costly mistakes. Reflecting on these factors can save time and resources in the long run.

Best Practices for Hydraulic Hose Maintenance and Replacement

Regular maintenance of hydraulic hoses is crucial. Check for wear and tear often. Look for cracks, bulges, or leaks. If any are found, replace them immediately. These small signs can signal bigger issues if ignored. Proper inspection can save you from costly repairs down the line.

When replacing hoses, consider the environment they're in. Temperature fluctuations and exposure to chemicals can affect hose lifespan. Choose materials that suit your specific conditions. This decision is often overlooked, leading to premature failures. Additionally, ensure the proper installation of your new hose. Misalignment can cause stress, leading to early wear.

Proper cleaning of hydraulic hoses is another vital practice. Dust and debris can accumulate, causing blockages. Simple routine cleanings can prolong the life of your equipment. However, be cautious with the cleaning methods used. Some chemicals might damage the hose material. Always refer to guidelines for safe cleaning practices.